Comparing Brass and Stainless Steel Valves

Which Material Fits Your Needs?

A Changing Landscape in Car Cleaning

When it comes to selecting materials for a valve system, the decision can have a lasting impact on performance, safety, and cost. Factors such as corrosion resistance, application environment, maintenance, and budget all come into play.

Brass and stainless steel are two of the most common materials used in valve manufacturing. Both have their own strengths, but depending on the project or system requirements, one may be a better fit than the other. Let’s break down the key distinctions between these two materials to help you make an informed choice.

Overview: Brass vs. Stainless Steel Valves

Each material brings unique characteristics to the table. Brass is a copper-zinc alloy valued for its ease of use, affordability, and decent resistance to corrosion, making it a staple in plumbing systems. On the flip side, stainless steel offers exceptional durability and is ideal for applications where extreme temperatures, pressure, or corrosive agents are present.

One major reason stainless steel often wins out in high-demand industries is its superior resistance to corrosion—an essential factor in marine, food processing, and chemical applications. However, that doesn’t mean it’s always the right pick. Brass is still widely used in residential and light commercial systems due to its machinability and lower cost.

The better option truly depends on the demands of your system. To help guide your selection, here’s a deeper look at the advantages and limitations of each.

Brass Valves: When Affordability Meets Functionality

Brass valves are commonly found in plumbing, HVAC, and low-pressure systems. Thanks to their balance of performance and price, they’re a go-to for many residential and commercial applications.

Advantages of Brass Valves:

-

Budget-friendly: More affordable than stainless steel, especially for bulk use.

-

Malleable and easy to install: Brass is easier to machine, weld, and modify on-site.

-

Good general corrosion resistance: Performs well in neutral pH environments.

-

Safe for drinking water (when lead-free): Brass can inhibit bacteria, making it ideal for potable water.

-

Thermal conductivity: Excellent for systems requiring heat transfer.

-

Reliable in moderate conditions: Brass valves are durable with proper maintenance in non-aggressive environments.

Potential Drawbacks:

-

Not suitable for highly corrosive environments: Brass doesn’t hold up well in saltwater or high-chlorine applications.

-

Lead content risks: Some brass alloys contain trace lead; opt for certified lead-free products for drinking water systems.

-

Vulnerability to dezincification: Exposure to certain water types can cause zinc to leach out, weakening the material.

-

Limited temperature and pressure tolerance: Not ideal for extreme operating conditions.

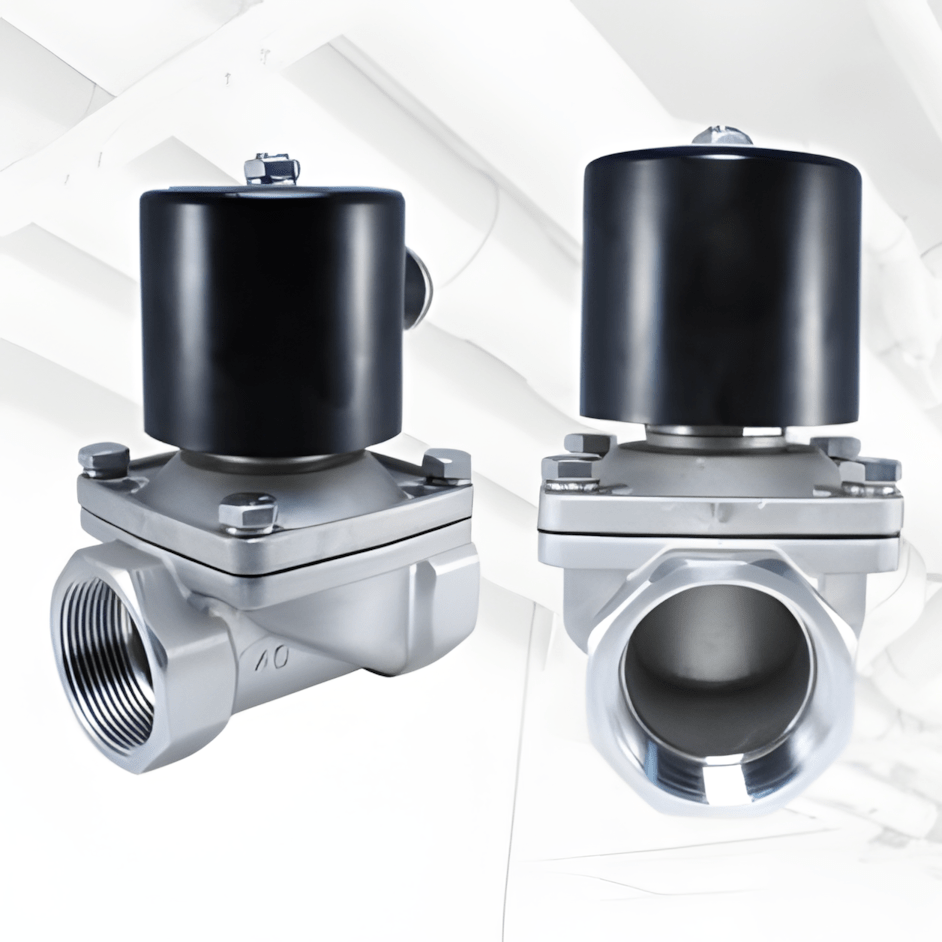

Stainless Steel Valves: Built for Tough Jobs

Stainless steel valves, including 304 and 316 grades, are favored in industries that demand high resistance to corrosion, durability under pressure, and compliance with hygienic standards.

Strengths of Stainless Steel Valves:

-

Exceptional corrosion resistance: Especially effective against harsh chemicals, acids, and saltwater (316-grade is preferred in marine settings).

-

FDA-approved for hygienic use: Smooth, non-porous surfaces make cleaning and sterilization easy.

-

Performs in extreme environments: Handles both high pressure and temperature better than brass.

-

Long lifespan: Stainless steel valves are designed to endure tough conditions with minimal degradation.

Considerations:

-

Higher cost: Expect a larger upfront investment compared to brass.

-

Heavier material: This can be a factor in weight-sensitive installations.

-

Lower thermal conductivity: Not as efficient as brass in thermal applications.

-

Magnetism in some grades: Certain stainless steels can become magnetic, which might not be suitable in some use cases.

Quick Comparison: Brass vs. Stainless Steel Valves

| Feature | Brass Valves | Stainless Steel Valves |

|---|---|---|

| Corrosion Resistance | Moderate | Excellent (ideal for harsh use) |

| Durability | Good with maintenance | Superior long-term performance |

| Cost | More affordable | Higher initial investment |

| Temperature Range | Limited | Wide, including high heat |

| FDA Approval | Not approved (unless lead-free) | Approved for food & beverage |

| Best Use Cases | General plumbing, HVAC | Industrial, marine, sanitary use |

Ideal Use Cases

Use Brass Valves When:

- You’re working with plumbing systems in residential or light commercial spaces.

- The system operates under moderate temperatures and pressure.

- You need a cost-efficient solution without heavy chemical exposure.

- The water source is not aggressive or heavily treated.

Choose Stainless Steel Valves When:

- You’re dealing with corrosive substances or saltwater environments.

- Your application must meet sanitary or food-grade standards.

- The system will be under high pressure or temperature conditions.

- You want maximum durability with minimal maintenance over time.

Corrosion Behavior in Both Materials

Both brass and stainless steel can experience corrosion, but in different forms and under different conditions.

Brass Corrosion Risks:

- Dezincification: Weakens brass by leaching out zinc in aggressive water environments.

- Stress Corrosion Cracking: May crack under strain in the presence of chemicals like ammonia.

- Galvanic Corrosion: Occurs when brass contacts a more noble metal like stainless in a moist environment.

Stainless Steel Corrosion Types:

- Pitting: Small, deep pits can form from chlorides or stagnant water.

- Crevice corrosion: Occurs in tight spaces with poor oxygen access.

- Intergranular corrosion: Can happen due to improper heat treatment.

- Stress corrosion cracking: Less common, but still a concern in extreme chloride-heavy environments.

Stainless steel 316 includes molybdenum, enhancing its resistance to many of these forms of corrosion compared to 304, which lacks this alloying element.

Car Wash Sales & ROI Overview

The car wash industry demonstrates strong revenue potential and ROI metrics, driven by operational efficiency and consumer demand.

Revenue Streams according to an industry report from IBIS World

-

Self-service car washes generate $40,000–$100,000 annually

-

Full-service operations (interior/exterior cleaning) yield $500,000–$900,000/year.

Profit Margins

Average margins range 10–20% when optimized6, with express exterior washes achieving higher multiples due to subscription models9.

ROI Timelines

Most automatic car washes recoup investments in 3–7 years, depending on factors like location and operational efficiency.

Frequently Asked Questions

Is stainless steel always better than brass?

Not always. Stainless steel excels in extreme or corrosive environments, but brass can be more cost-effective and practical for general plumbing and moderate conditions.

Can brass valves be used for drinking water?

Yes, if they are certified lead-free. Always check product specifications for potable use.

Will brass corrode in saltwater?

Yes. Brass is not recommended for marine applications due to its poor performance in salt-heavy environments.

What makes stainless steel suitable for food and beverage use?

Its non-porous surface resists bacteria and is easy to clean, which is why it’s FDA-approved for sanitary applications.

Why is dezincification a concern with brass?

In aggressive water conditions, zinc can leach out, compromising the strength and sealing ability of the valve.

Final Thoughts: Prevention is the Best Fix

There’s no one-size-fits-all when it comes to valve material selection. Brass is a practical, budget-friendly choice for standard residential and commercial plumbing. Stainless steel, however, is the material of choice for systems that demand longevity, resistance to harsh elements, or sanitary compliance.

Need help selecting the right valve? Contact our team or browse our range of brass and stainless steel valve options to find what works best for your project.

Need a New Valve or a Second Opinion?

At Atlantic Valves, we stock a wide range of motorized ball valves to fit every system—from small residential setups to large-scale industrial operations.

✔ Fast, reliable shipping – most orders ship within 1 business day

✔ Expert support – personalized advice to help you choose the right valve

✔ Trusted quality – precision-engineered components built to last

Contact our team for expert guidance on your next installation or repair.